Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

نموذج: Battery System

علامة تجارية: HTD

مكان المنشأ: الصين

تحديد موضع المنتج:

يعد قضيب الاستشعار المتكامل HTD مكونًا ذكيًا داخل وحدة البطارية الذي يحقق جمع التيار المتكامل وأخذ عينات الجهد والحصول على إشارة درجة الحرارة. ومن خلال دمج الدوائر المطبوعة المرنة (FPC)، وموصلات النحاس/الألومنيوم، والهياكل العازلة، فإنها تحل محل أحزمة الأسلاك المنفصلة التقليدية. يقوم بوظائف بسبار عالية التيار بينما يقوم في نفس الوقت بجمع إشارات جهد الخلية ودرجة الحرارة في الوقت الفعلي وإرسالها إلى نظام إدارة البطارية (BMS). إنه مكون أساسي لتعزيز الذكاء ودقة الإدارة وسلامة حزمة البطارية.

معلمات الأداء الرئيسية لقولبة الإدخال :

| Category | Specific Parameters | Test Standard |

| Signal Acquisition Component | FPC/FFC flexible circuit (PCB optional), supports simultaneous voltage/temperature acquisition | IEC 60664-1 |

| Conductive Material | Aluminum busbar (AL1000 series) or copper-clad aluminum composite, Cu layer 30%-40% | ASTM B209 |

| Sampling Accuracy | Voltage sampling error ≤ ±1mV; Temperature sampling accuracy ±1% (NTC/PTC) | ISO 21782 |

| Insulation & Withstand Voltage | Insulation layer withstand voltage ≥2500V AC, Protection level IP67 | ISO 20653 |

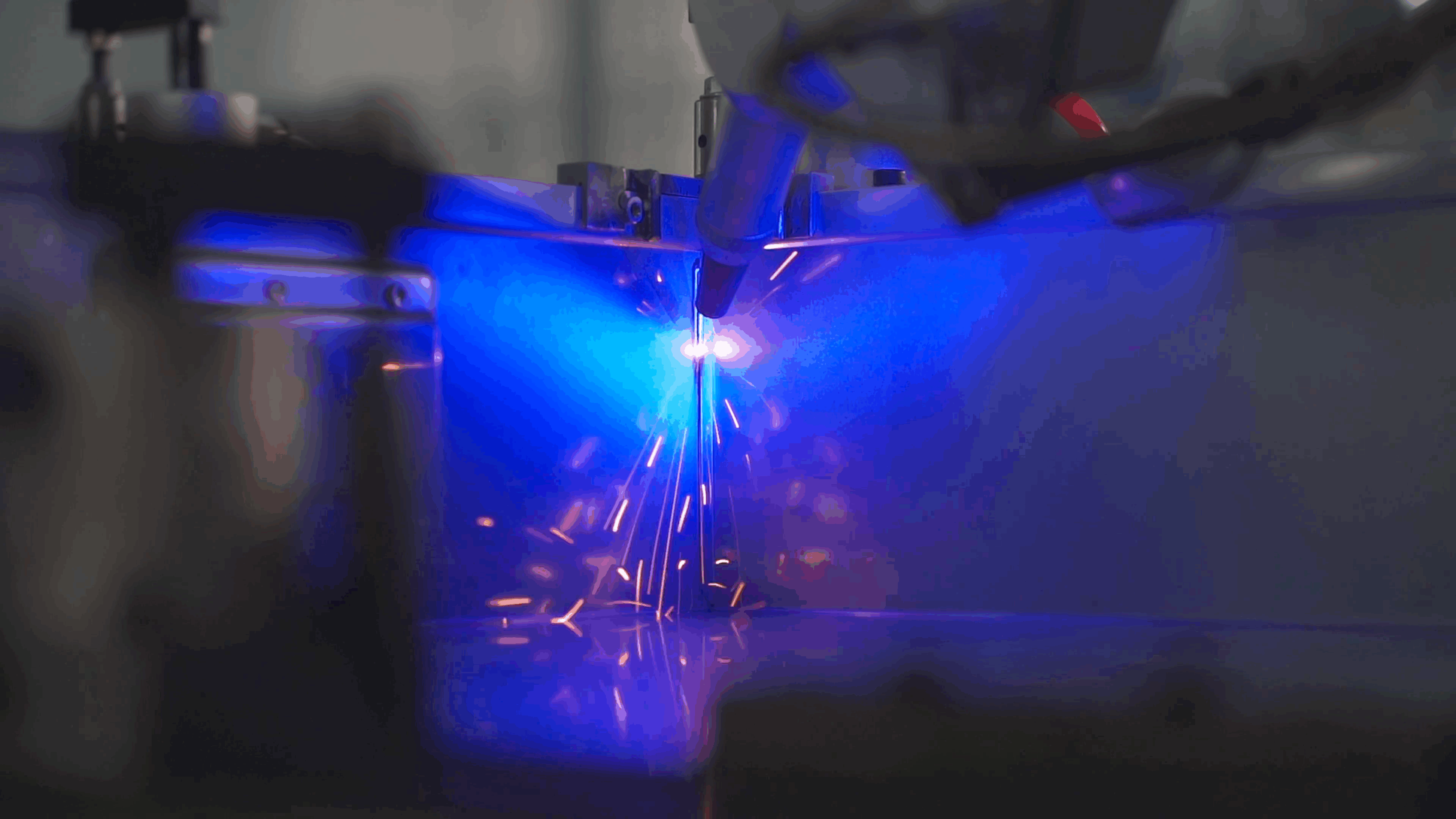

| Integration Process | Laser welding (depth ≥0.5mm) or bolted connection (torque accuracy ±0.5N·m) | IEC 60947 |

| Insulation Treatment | Hot-pressed insulating film/Injection molded bracket/Vacuum formed spacer, customizable | UL 94 V-0 |

| Operating Temperature |

-40°C to +125°C (FPC component);

-40°C to +150°C (Aluminum busbar)

|

GB/T 28046 |

| Lightweight Design |

Over 50% weight reduction and 60% volume reduction compared to traditional wiring harness solutions |

Real-vehicle validation |

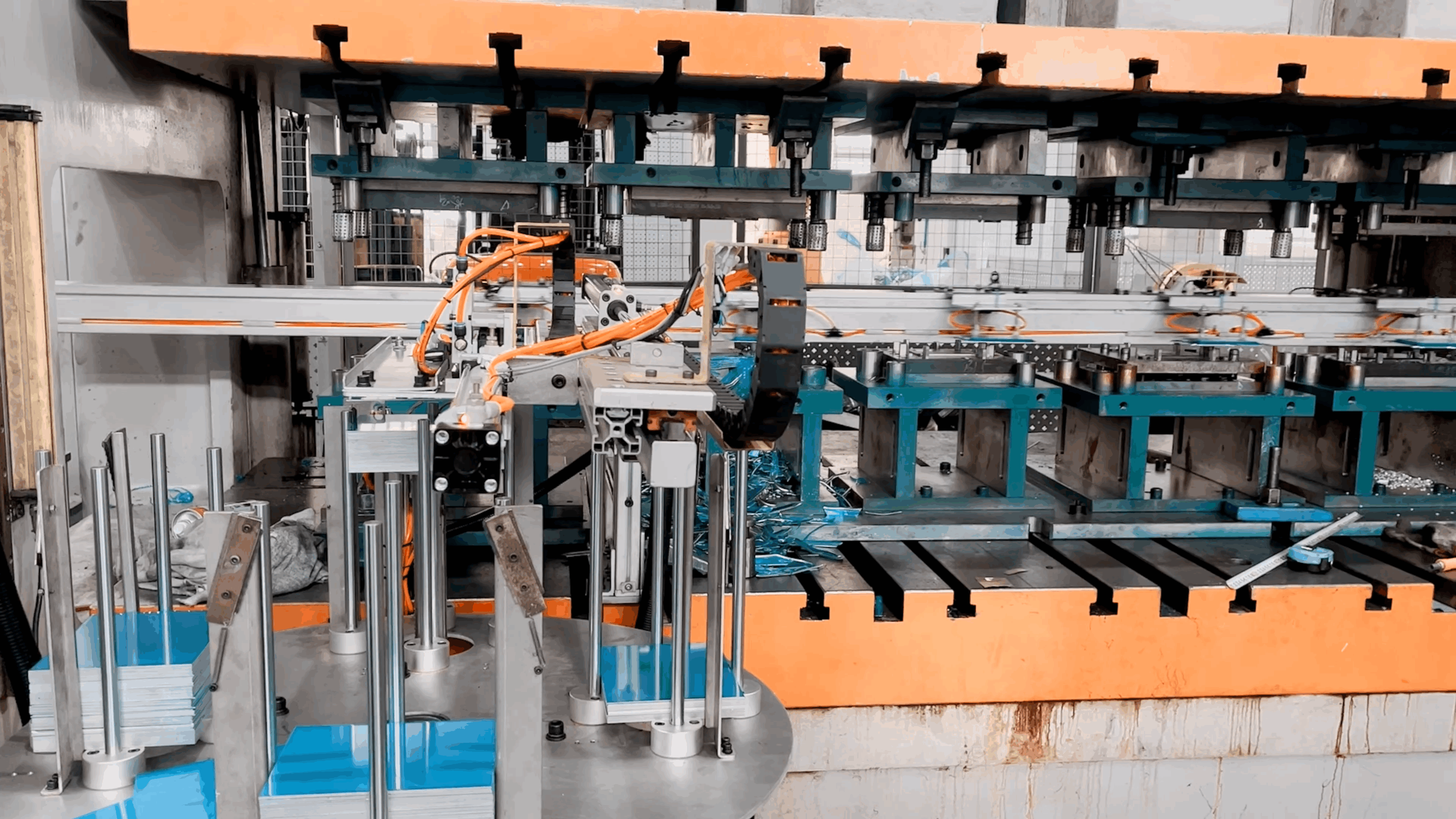

| Step | Core Process | Key Technical Points | Output Standard |

| 1 | FPC Circuit Fabrication | R2R micro-etching, trace width/spacing accuracy ±0.05mm | Impedance consistency ≤ 3% |

| 2 | Component Mounting & Soldering | SMT + reflow soldering, NTC weld porosity < 5% | Sampling accuracy ±1% |

| 3 | Busbar & FPC Integration | Hot-press film lamination or injection molded bracket fixation | Insulation withstand voltage ≥2500V |

| 4 | Laser Welding & Inspection | Welding hole positioning for nickel sheets, X-Ray inspection of weld quality | False welding rate < 0.1% |

| 5 | Full Function Test | Continuity/Insulation withstand voltage/NTC temperature drift test, MES data traceability | Defect rate ≤ 0.1% |

The file is encrypted. Please fill in the following information to continue accessing it

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.